EG Roofing Nails

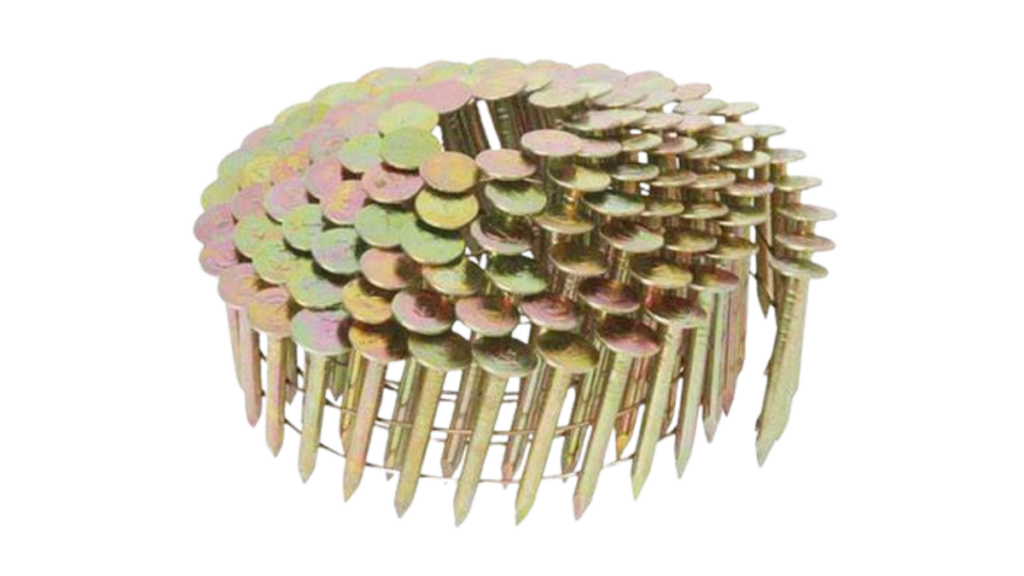

EG Roofing Nails (Electro-Galvanized Roofing Nails)

EG (Electro-Galvanized) roofing nails are specifically designed for securing roofing materials such as shingles, felt, and flashing. The electro-galvanized coating provides a layer of corrosion resistance, making them suitable for outdoor use.

Features of EG Roofing Nails:

- Material: Made of steel with an electro-galvanized (EG) zinc coating to resist rust.

- Head: Large, flat head for better holding power on roofing materials.

- Shank: Can be smooth or ring-shanked for increased grip.

- Length: Typically ranges from 3/4 inch to 2 inches, depending on the roofing material.

- Coating: Electro-galvanized zinc coating offers basic rust protection but is less durable than hot-dipped galvanized nails.

Uses of EG Roofing Nails in Construction:

- Installing Asphalt Shingles: Secures shingles firmly to the roof deck.

- Fixing Roofing Felt or Underlayment: Helps keep roofing underlayment in place.

- Attaching Metal Flashing: Used to fasten metal sheets to prevent leaks.

- General Roofing Applications: Suitable for various roof types, but mainly used in moderate climates.

Types of EG Roofing Nails:

- Smooth Shank EG Roofing Nails: Standard nails for basic roofing tasks.

- Ring Shank EG Roofing Nails: Provide extra grip, reducing the chance of nails loosening over time.

- Short EG Roofing Nails: Used for thinner materials or secondary layers.

- Long EG Roofing Nails: Ideal for thick roofing materials or multiple layers of shingles.

How to Choose the Right EG Roofing Nail?

- For standard asphalt shingles: 1 to 1-1/4-inch smooth shank nails are ideal.

- For windy areas or thick shingles: Use ring-shank nails for extra grip.

- For humid or coastal areas: Consider hot-dipped galvanized or stainless steel nails for better corrosion resistance.